Our Clients – service centers – that decided to implement Positive Productivity® acknowledge that this Performance Management and Continues Improvement System solves the 4 key needs in the sector:

1

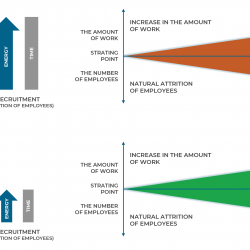

How to change the strategy from the recruitment model onto the focus on optimization?

2

How to address 6 key strategic challenges defined by the long-term strategy?

3

How to address 6 key strategic challenges defined by the long-term strategy?

4

Unfortunately for most of the service centers it is not the opportunity but rather a Cost Gap – when the strategy focuses the organizational effort on recruitment and introducing new employees it leaves very little or no time and energy for optimization.

Optimization Opportunity Gap creates the business case for investment into performance management and continues improvement culture since it shows that we can:

- Enable the huge savings of costs which used to be spent on recruitment, job introduction and salary for the new employees.

- Enable the shift of energy of employees from introducing new joiners to the team to improvements that create the situation when the need for recruitment is far lower.

This is a win-win strategy for both management and the staff of the service centers.

"Now we understand, that the most important is optimization, not recruitment."

Tomasz Brożyna, Regional COO East Europe, Mondial Assistance, member of Allianz Group

Find out how Mondial Assistance has changed their business model – shifting from recruitment to optimization:

Find out more what is the financial value of the Optimization Opportunity Gap in your service organization. Find out more…

| OVERALL BUSINESS NEEDS | |

| Strategic needs based on our clients experiences | Our strategic solution |

| Our Center needs to implement a continuous improvement culture/ constant growth of productivity is our strategic goal | 1. Well-structured methodology which ensures the continuous improvement of results for years to come |

| We have a high rate of staff turnover, we constantly recruit and train new people, this consumes a lot of time, energy and money | 2. Mindshift towards investing in current employees to optimize the use of time and energy, and away from the recruitment and training of new employees |

| NEEDS RELATED TO EMPLOYEE ENGAGEMENT | |

| Strategic needs based on our clients experiences | Our strategic solution |

| We need to increase engagement and achieve substantially better performance at the same time, and we don’t know how to achieve both | 3. Team habits which ensure synergy effects between productivity and employee engagement |

| Many of our employees focus on their own tasks and problems, they do not take ownership of improvement initiatives | 4. Mindshift of employees toward regular best practices sharing, collaboration on problem solving and work balance among the team |

| NEEDS RELATED TO EMPLOYEE PRODUCTIVITY | |

| Strategic needs based on our clients experiences | Our strategic solution |

| There are many optimization tools, but we don’t know which to select to ensure that our goals are met and that results will be sustained. | 5. Structured methodology with simple tools and a step by step approach providing measurable results through the implementation of regular team habits. |

| We need to standardize our processes, we need to be prepared for the new system implementation | 6. Automation is fast and affordable if the processes are standardized. Improvement culture, the implementation of best practices and standards used by all employees is the primary step |

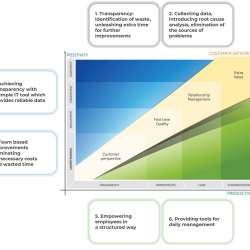

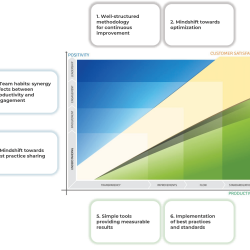

Strategic needs mapped on the Positive Productivity® Model:

| OVERALL BUSINESS NEEDS | |

| Operational needs based on our clients experiences | Our operational solution |

| We need improvements, we need fast change, we need results but our employees have no time for optimization | 1.Introduce transparency which enables clear identification of major sources of waste and problems in the organization – “low hanging fruit”. Their fast elimination unleashes employees’ time for further improvements |

| Our clients are not satisfied with our service / we struggle with quality and timeliness problems | 2. Collecting relevant data, measuring and visualizing problems, introducing teamwork on root cause analysis and elimination of the sources of problems |

| NEEDS RELATED TO EMPLOYEE ENGAGEMENT | |

| Operational needs based on our clients experiences | Our operational solution |

| We don’t have data on how the time of our employees is spent | 3.Empowering employees in a structured way. When employees see what they can change and are invited to change it – they get involved in proposing improvements and feel that they can make an impact |

| Our operating costs are too high – we do not know how and where we are losing efficiency | 4.Providing tools for daily management, giving feedback based on objective data, team problem solving capabilities |

| NEEDS RELATED TO EMPLOYEE PRODUCTIVITY | |

| Operational needs based on our clients experiences | Our operational solution |

| The level of employee engagement is too low and morale needs to be improved | 5.Introduce transparency with simple IT tool which provide reliable data by reporting all types of activities online |

| Managers have constant challenges with proper team management and giving constructive feedback to employees | 6.Service organizations have common costs / sources of wasted time which can be identified, measured and eliminated by team based improvements |

Operational needs mapped on the Positive Productivity® Model:

4. How to prepare your organization for automation?

Process automation is a trend that carries with it a number of myths and traps. Not being aware of them can prove harmful for the organization wishing to implement automation by exposing it to significant costs and misused time. Meanwhile, the key aspect here is to prepare for the process through engaging your employees in optimization and standardization based on well-structured methodology. Proceed to implement automation sensibly, quicker and cheaper.

LEARN MORE: